Leading retail apparel Paul Frank Singapore implements RFID for Inventory

Leading apparel Company Clubman Singapore Pte Ltd is rolling out Intrasys RFID Solution to its Paul Frank locations, with 8 of its store scheduled to have the technology integrated by September 2014, and its Malaysia counterpart following next year. With RFID, Paul Frank gain greater visibility into item-level locations, changing how they operate their stores and warehouses.

Our RFID Solution delivers

- 100% store inventory visibility, allowing for a robust omni-channel shopping experience.

- Mobile Inventory Management through RFID, improving stocktaking performance by 800%.

- Real-time update within 5 seconds of read, allowing for improved decision making.

Challenge

In order to improve inventory accuracy and on-shelf availability of products, Paul Frank explored the possibility of implementing a RFID system for improved productivity. Paul Frank decided that a total RFID-enabled store and warehouse monitoring solution would be more beneficial to the company, as it would allow operators and staff locate merchandize, improve stock take process, and to prevent loss of items.

Paul Frank chose Intrasys' Inventory Management and Stock Take Solution because the web-based system and its ERP system performed well together. The RFID solution is also able to provide real-time updating inventory level and location data. However, another challenge for Paul Frank was that they do not physically own some of the store counters, and Intrasys worked around by provided highly customized version of the Inventory Management System to suit their needs.

The Intrasys' Inventory Management and Stock Take Solution has not only delivered, but also exceeded the expectation of Paul Frank. With RFID-enabled setup for its entire operation, staff can now work in an environment with full visibility of inventory. The accuracy of reads is 100% in real-time and requires less work. This unlocks a wealth of possibilities in Intrasys' roadmap towards a robust omni-channel shopping experience for all our customers.

How It Works

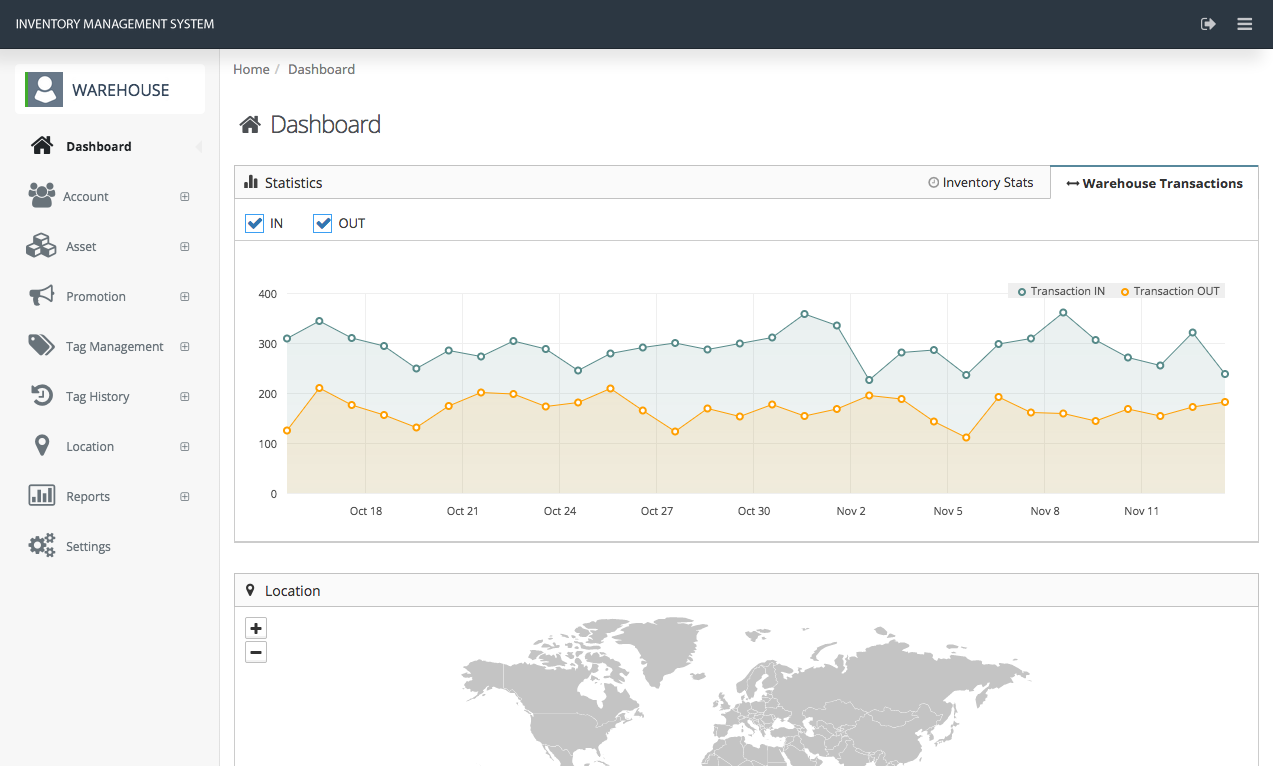

The Paul Frank Warehouse is issued with 2 Mobile RFID Readers installed with Intrasys’ Inventory Management System. All items are being tagged individually and mass consigned by RFID scanning. All movements, include stock in, stock out and transfer, are registered and track in the system. All transactions can be retrieve from the web-based Inventory Management System and can be exported in numerous formats.

All Paul Frank retail stores carry a Mobile RFID Reader. Upon receipt of inventory, staff stocks in by scanning all items in the shipment.

Intrasys' Tags, powered by Alien Higgs 4 chips, provide accurate read up all the time for the operator. Up to 300,000 inventory are tagged in a year, with all being monitored via RFID readers. On picking up of any inventory, data from the reader is transferred to the central Inventory Management Database to provide real-time feedback on the inventory information. All actions performed and item details can be retrieved in real-time from anywhere.

Paul Frank is now able to continually monitor inventory in their warehouse as well as for all their stores. This helps both staff and management to easily locate inventory, and gives management additional information that can be used in conjunction with ERP system to provide useful analytics. The RFID system also improves security by implementing accountability in each action taken automatically. For example, the management would be able to see the last known location of a missing inventory, and who was involved in the action.

Benefits

Second, management now has 100% visibility of the warehouse and stores. Once any inventory movement is required, the item movement is tracked by RFID scanning process and entered to the location of the warehouse.

Operators and employees are able to easily locate items, and management is able to have accurate, real-time information on warehouse inventory, all the while expending less time and effort looking for and inventorying items. This complete warehouse and store visibility helps prevent costly mistakes, improves ability to find inventory, and provide useful data to allow management to optimize the warehouse process.

Third, store operator benefit from the increased efficiency in stock taking processes. What used to take 8 employees and 4 hours now only requires 2 employees in half the time, achieving 800% increased efficiency.

Due to the success of the Intrasys' Inventory Management and Stock Take Solution, Paul Frank is considering to deploy the same setup for its future warehouses and retail outlets.